Technologie heat converter

Innovative heat converter

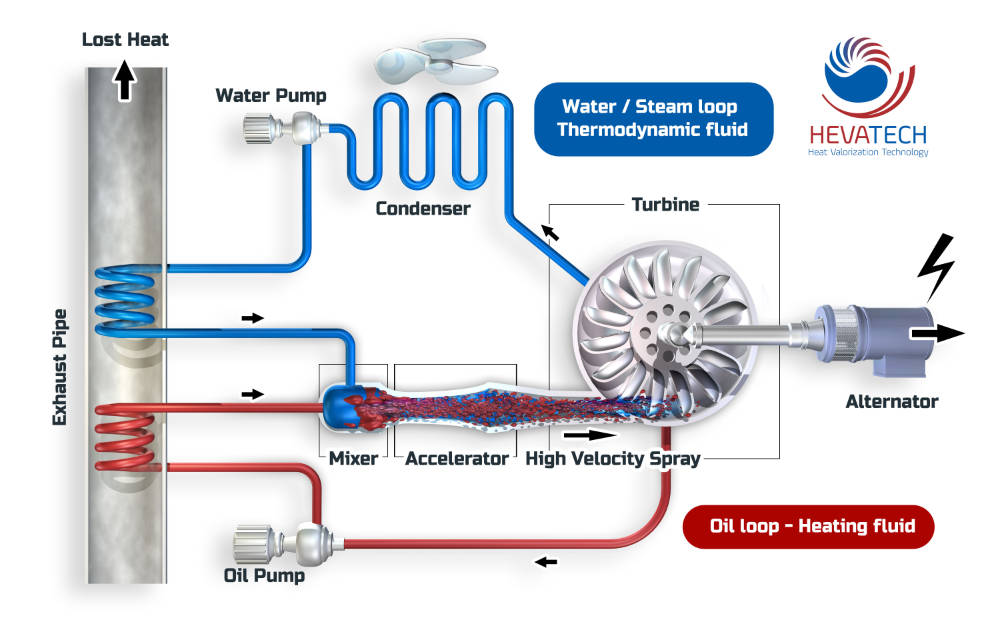

TURBOSOL technology is based on a combination of 3 concepts:

- Waste heat is captured by two fluids: a heat-transfer fluid (oil), which collects high temperatures and a thermodynamic fluid (water/steam), which valorises low to intermediate temperatures.

- A two-phase accelerator triggers a strong acceleration of the mix during a quasi-isothermal expansion. Thermal energy is then converted into kinetic energy in the oil droplets.

- A Pelton-type impulse turbine is employed, renowned for its robustness and high performance. Moreover, as it rotates at low speed, power loss is avoided.

HEVATECH owns its TURBOSOL technology. It is a completely innovative product, which is protected with a few patents in several countries around the world (Japan, Canada, USA, Brazil…).

Economically competitive

Its easy use and robustness give TURBOSOL technology a distinct economic advantage over its competitors:

- A 4-year return on investment, twice as fast as directly competing ORC solutions.

- The turnkey target cost for TURBOSOL technology comes to €k 3-3.5 per kWe installed depending on the conditions (exchangers, power, environment, cold source, etc.) for mass production from 2022.

Our documentation

EN - TURBOSOL: Innovative heat-to-power conversion technology